Device Description:

JB-BZ-2L series semi-automatic bottle blowing machine is suitable for polyester (PET) mineral water bottles, beverage bottles, oil bottles, cosmetic bottles, pesticide bottles, medicine bottles and polypropylene (PP), polycarbon (PC), PMMA, PS Production of high-temperature resistant ready-made products. This model has the advantages of stable operation, low power consumption, wide applicability, reasonable structure and convenient maintenance.

Features:

1. The HQ series infrared rotary oven adopts unique design from Japan and Germany, so it consumes less power; it uses infrared lamps for heating, strong penetrating power, heating by the rotation of the preform, orbital revolution, uniform heating, fast and reliable; heating zone The width of the lamp tube, reflector plate and high temperature can be adjusted to suit the heating of preforms of different structures, and there is an automatic temperature exhaust device to ensure the constant temperature of the drying tunnel;

2. Each action is driven by an air cylinder, no oil pump is used, and it has the advantages of no pollution and low noise. It adopts high pressure and double crank arm connecting rod for mold clamping, and strong mold clamping force;

3. There are two methods of operation: manual and fully automatic; safe, reliable and unique valve position design makes the gas path clear at a glance;

4. It has the advantages of low investment, high efficiency, low power consumption, convenient operation, simple maintenance and safety.

5. The bottle body is free from pollution and the scrap rate of the bottle is less than 0.1%

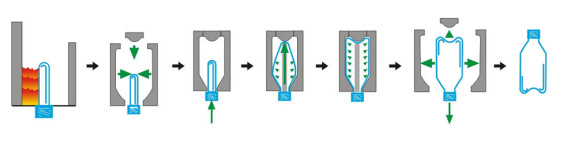

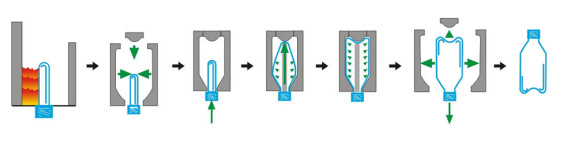

Bottle blowing process: