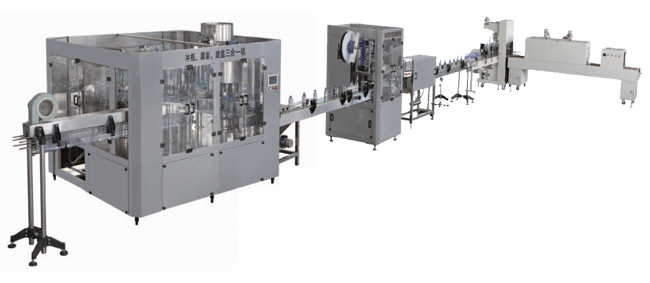

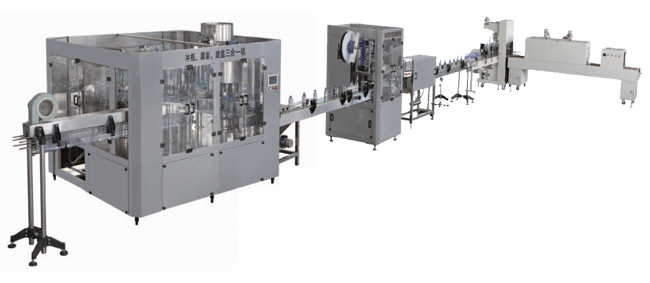

This machine is mainly used for beverage filling operations. This machine will rinse, fill and seal three

The functions are combined in one body, and the whole process is automated, suitable for polyester bottles,

Plastic bottles are filled with mineral water and pure water. Easy adjustment of applicable bottle types for each part

For example, simple and fast. The filling method adopts a new type of micro negative pressure filling, which is stable and

Rely on, so compared with the machine of the same specification, the benefit of this machine is greater.

This machine adopts advanced OMRON programmable controller (PLC) to control the machine

Automatic operation, air feeding device is adopted for bottle feeding, and the chain of output bottle adopts adjustable speed

It cooperates with the inverter of the host machine to make the bottle running more stable and reliable. Photoelectric inspection

The running status of each component is measured, so the degree of automation is high, the operation is simple, and the

Ideal equipment for material manufacturers.

Model GL18-18-6 GL24-24-8 GL32-32-10 GL-40-40-12 GL50-50-14

Production capacity (500ml b/h) 6000 10000 14000 18000 24000

Total power (KW) 7.68 9.18 10.28 11.28 12.38