HOTLINE

HOTLINE

1. Introduction to reverse osmosis equipment:

The reverse osmosis equipment is to pass the raw water through a fine filter, granular activated carbon filter, compressed activated carbon filter, etc., and then pressurize by a pump, using a pore size of 1/10000μm (equivalent to 1/6000 the size of E. /300) reverse osmosis membrane (RO membrane), which turns high-concentration water into low-concentration water, and at the same time isolates all the impurities mixed into the water such as industrial pollutants, heavy metals, bacteria, and viruses, so as to achieve the physical and chemical drinking regulations Indicators and hygienic standards, producing pure to pure water, is the best choice for the human body to replenish high-quality water in time. So people call this water production machine a reverse osmosis pure water machine.

Reverse osmosis is a modern new type of pure water treatment technology. Through reverse osmosis element to improve the purity of water quality, remove impurities and salt contained in the water. The purified water we drink daily is treated by reverse osmosis equipment, and the water quality is clear.

The first country in the world to use reverse osmosis technology is the United States, which invented membrane separation technology powered by power difference. With the promotion of this technology, my country began to use reverse osmosis technology. The pure water equipment on the market uses reverse osmosis membrane treatment technology, and has undergone certain improvements and design innovations in my country. The technology is very mature.

A reverse osmosis membrane is designed in the reverse osmosis purified water equipment. The pressure on both sides of the membrane is different. The pressure on both sides is used as the driving force to force the raw water to pass through the reverse osmosis membrane. The low salt concentration will permeate to the high concentration salt direction. The equilibrium state that can be achieved is the osmotic pressure of the liquid. When the pressure on one side of the salt water is to the osmotic pressure on the other side, the reverse flow will occur, and the reverse osmosis process will occur.

The reverse osmosis pure water equipment adopts this technology, and adopts the intelligent control of automatic water supply and water cut off. This is the pure water equipment

2. System composition:

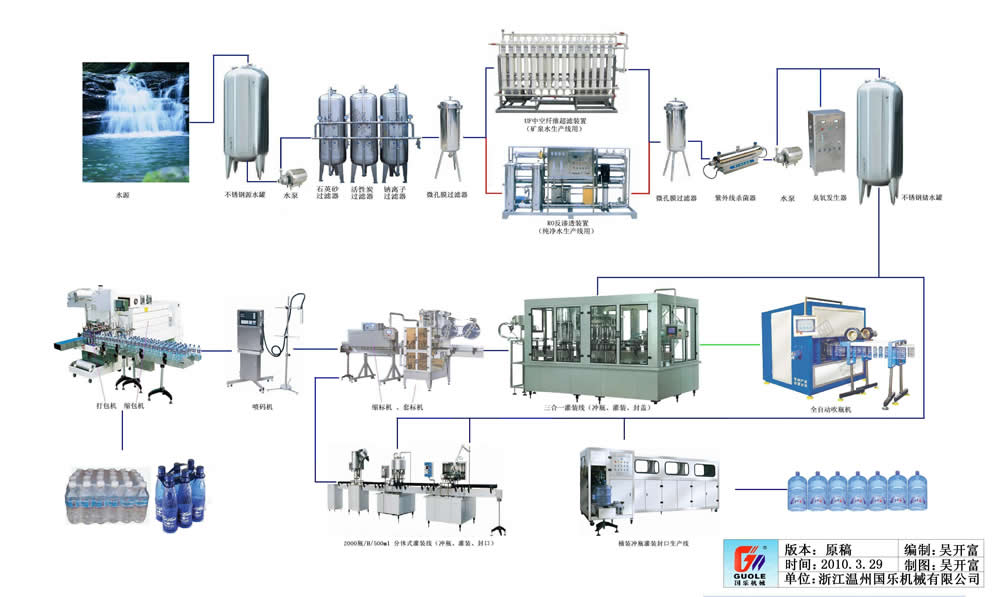

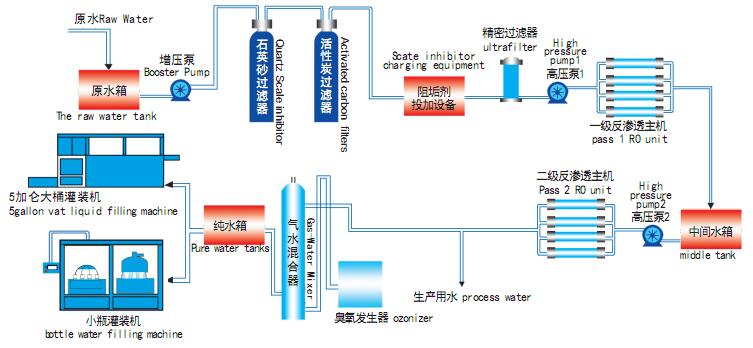

Pretreatment: generally includes raw water pump, dosing device, quartz sand filter, activated carbon filter, precision filter, etc. Its main function is to reduce the pollution index of raw water and other impurities such as residual chlorine to meet the requirements of reverse osmosis. The equipment configuration of the pretreatment system should be determined according to the specific conditions of the raw water.

Reverse osmosis: It mainly consists of multi-stage high-pressure pumps, reverse osmosis membrane elements, membrane shells (pressure vessels), and supports. Its main function is to remove impurities in the water and make the effluent meet the requirements of use.

Cleaning: Mainly consists of cleaning water tank, cleaning water pump, and precision filter. When the reverse osmosis system is polluted and the effluent index cannot meet the requirements, it is necessary to clean the reverse osmosis to restore its function.

Electrical control: It is used to control the normal operation of the entire reverse osmosis system. Including instrument panel, control panel, various electrical protection, electrical control cabinet, etc.

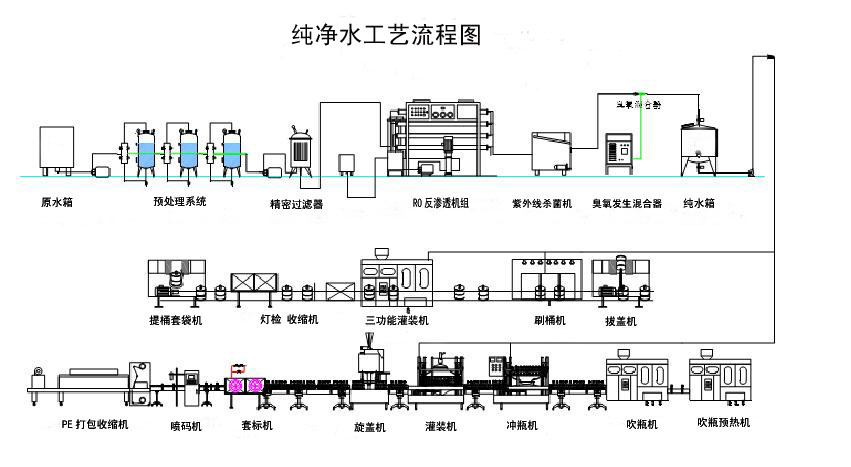

3. Process flow:

Raw water tank: store raw water, used to settle the large sediment particles and other sedimentable substances in the water. At the same time, the impact of unstable water pressure in the raw water pipe on the water treatment system is buffered. (Such as the pressure sensor response caused by too low or too high water pressure).

Raw water pump: constant system water supply pressure, stable water supply.

Multi-media filter: a filter with multiple layers of filtration, the main purpose is to remove the material with particles above 20um, such as sand, rust, colloidal matter, suspended matter, etc. contained in the raw water. Manual valve control or fully automatic controller can be selected Perform a series of operations such as backwashing and forward washing. Ensure the water quality of the equipment and extend the service life of the equipment.

Activated carbon filter: The system uses a nutshell activated carbon filter. The activated carbon can not only adsorb electrolyte ions, but also perform ion exchange adsorption. Activated carbon adsorption can also reduce the oxygen consumption (COD) of potassium permanganate from 15mg/L (O2) to 2~7mg/L (O2). In addition, the concentration of adsorbed replication on the surface increases due to the adsorption effect. It plays a catalytic role, removes pigments, peculiar smells, a large amount of biochemical organic matter in the water, reduces the residual chlorine value of the water and pesticide pollutants, and removes the trihalide (THM) and other pollutants in the water. At the same time, the equipment has a self-maintenance system and the operating cost is very low.

Ion softening system/dosing system: The R/O device is for the concentrated discharge of dissolved solids and the utilization of fresh water, to prevent CaCO3, MgCO3, MgSO4, CaSO4 from the concentrated water side, especially the concentrated water side of the last membrane module of the RO device The concentration product of BaSO4, SrSO4, SiSO4 is greater than its equilibrium solubility constant and crystallizes out, which damages the original characteristics of the membrane. Before entering the reverse osmosis membrane module, an ion softening device or an appropriate amount of scale inhibitor should be used to prevent carbonate , SiO2, sulfate crystals precipitate out.

Precision filter: The use of precision filters to remove suspended solids, non-curved particles and colloids remaining in the influent water makes the RO system and other follow-up equipment safer and more reliable. The filter element is a 5um melt blown filter element, the purpose is to remove the impurities greater than 5um leaked by the upper filter unit. Prevent it from entering the reverse osmosis device to damage the surface of the membrane, thereby damaging the desalination performance of the membrane.

Reverse osmosis system: The reverse osmosis device uses enough pressure to separate the solvent (usually water) in the solution through the reverse osmosis membrane (or semi-permeable membrane), because this process is opposite to the direction of natural osmosis, so it is called Reverse osmosis. The reverse osmosis method can adapt to all kinds of raw water with salt content, especially in water treatment projects with high salt content, and can obtain good technical and economic benefits. The reverse osmosis method has improved desalination rate, high recovery rate, stable operation, small footprint, and simple operation. While the reverse osmosis equipment removes salt, it also removes most of the bacteria, colloids and large molecular weight organic matter.

Ozone sterilizer/Ultraviolet sterilizer (optional): Kill bacteria caused by secondary pollution and completely ensure the sanitary indicators of finished water.

Raw water → raw water tank → raw water pump → multi-media filter (quartz sand filter) → activated carbon filter → water softener (adding scale inhibitor) → precision filter → high pressure pump → first-stage reverse osmosis (RO) device → Ultraviolet sterilization device (ozone sterilization device) → water point

4. Main purpose

⒈Prepare pure water and high-purity water required for the production of electronic industry such as kinescope glass bulb, kinescope, liquid crystal display, circuit board, computer hard disk, integrated circuit chip, monocrystalline silicon semiconductor and other processes;

⒉Producing thermal and thermal power boilers, softened water and demineralized pure water required for feed water for medium and low pressure boilers in factories and mines;

⒊Prepare pure water for medical infusions, injections, pharmaceuticals, biochemical products, sterile water for medical use and pure water for artificial kidney dialysis required by the pharmaceutical industry;

⒋Pure drinking water, distilled water, mineral water, wine brewing water and pure water for blending in the beverage (including alcohol) industry;

⒌The production of domestic water and drinking water from sea water and brackish water;

⒍Preparation of deionized water for electroplating process; pure water for battery (battery) production process; surface coating and cleaning water for automobiles, household appliances and building materials; pure water for coated glass; hardening and removal required for textile printing and dyeing process brine;

⒎Petrochemical industry such as chemical reaction cooling water; process pure water used in the manufacturing process of chemical agents, fertilizers, fine chemicals, and cosmetics;

⒏High-quality water supply network system and swimming pool water purification for hotels, buildings, community airport real estate properties;

⒐Circuit board, electroplating, electronic industry wastewater treatment and reuse;

⒑ Treatment of wastewater and garbage leachate in domestic, hospital, tanning, printing and dyeing, papermaking industries;

5. Application areas:

Reverse osmosis membrane technology is used in power plant boiler feed water, ultrapure water treatment in the electronics and semiconductor industries, pure water treatment in the chemical and pharmaceutical industries, food, beverage, drinking water treatment, seawater, brackish water desalination, metallurgy, light industry, electroplating and leather It has been widely used in wastewater treatment and other industries.